Everything About Screen Printing: A Comprehensive Overview to Its Advantages and Applications

Screen printing has a rich history and offers many industries today. Its advantages, consisting of vivid shades and longevity, make it an appealing selection for bulk production. Numerous makers and companies use this method for various applications, from style to advertising things. Comprehending the screen printing procedure is essential for those looking to access its possibility. What complies with is an exploration of its benefits and techniques that can transform innovative ventures.

The Background of Screen Printing

The advancement of screen printing is a remarkable journey that traces back to ancient people. The technique can be linked to the Chinese, who created a type of stenciling as early as the Tune Empire (960-1279 AD) making use of silk and all-natural inks. By the 18th century, screen printing made its method to Europe, where artisans embraced and adapted the method for material design.

In the 20th century, screen printing gained popularity in the USA, specifically with the surge of commercial printing and marketing. Artists like Andy Warhol made use of the technique, raising it to an art kind. The introduction of artificial inks and harmonize fabrics better reinvented the procedure, making it much more versatile and efficient. Today, screen printing is widely utilized in different industries, from textiles to signage, showcasing its enduring relevance and adaptability with the ages.

Advantages of Screen Printing

Screen printing uses countless advantages that make it a recommended option for numerous organizations and musicians. One considerable advantage is its versatility; it can be used to various materials such as plastics, metals, and fabrics, enabling for a wide range of applications. Additionally, screen printing provides vivid shades and sharp pictures, making sure top notch results that stand apart.

Applications of Screen Printing

Applications of screen printing are diverse, extending numerous industries and objectives. This flexible strategy is widely utilized in textiles, permitting for lively designs on apparel, hats, and devices. In the marketing items industry, companies frequently rely on screen printing to develop personalized items such as shopping bag, water containers, and banners, improving brand name presence.

Additionally, screen printing locates usage in electronic devices, where it is used to apply conductive inks on circuit card. The auto market additionally benefits from this approach, using it for attractive aspects and security labels. The art neighborhood accepts screen printing for producing minimal version artworks and posters, offering artists a means to recreate their job with accuracy. Ultimately, the product packaging sector utilizes screen printing for item labeling, making sure that branding is both appealing and long lasting. Generally, screen printing's adaptability makes it an important tool across countless areas.

The Screen Printing Refine

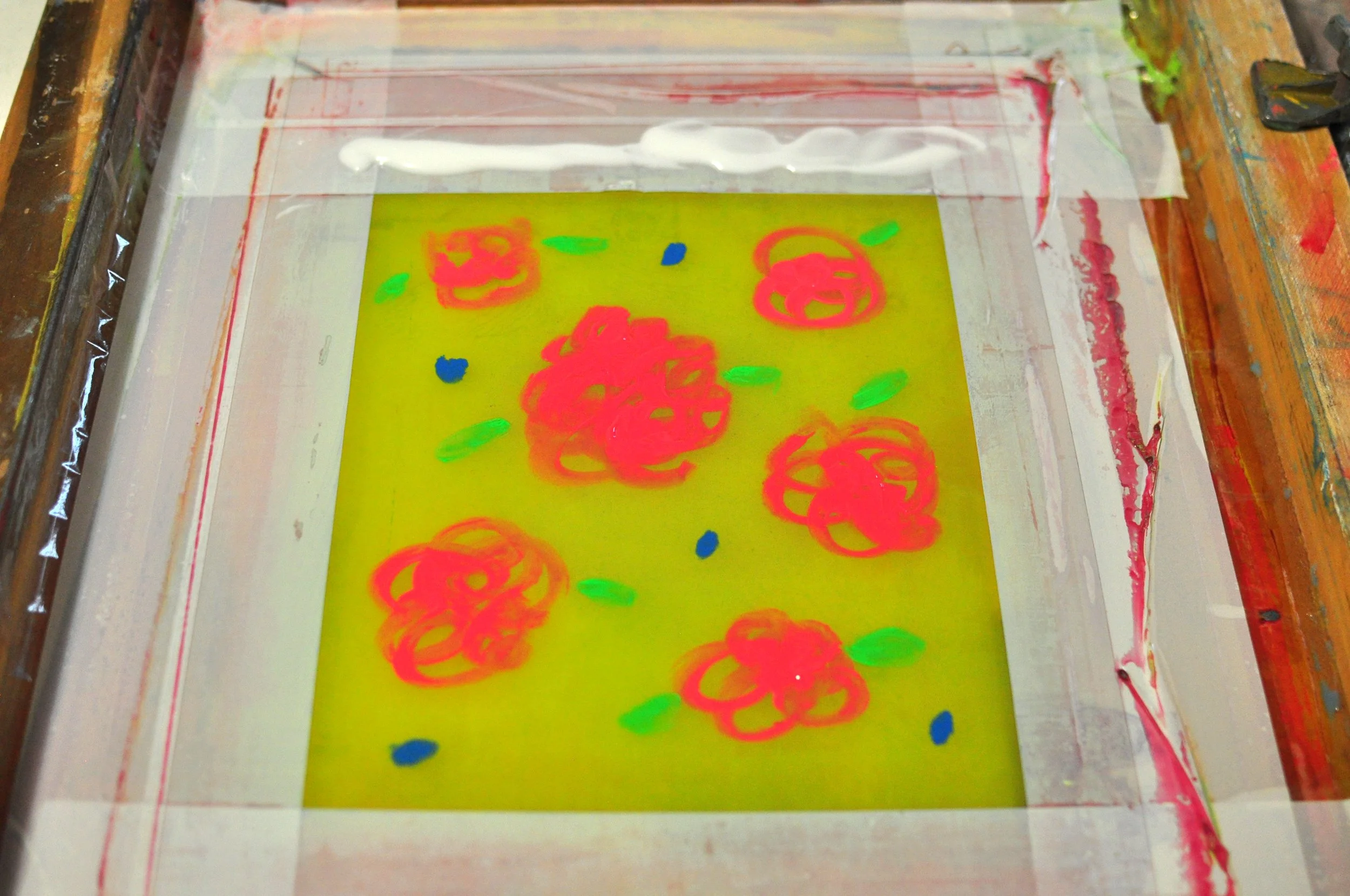

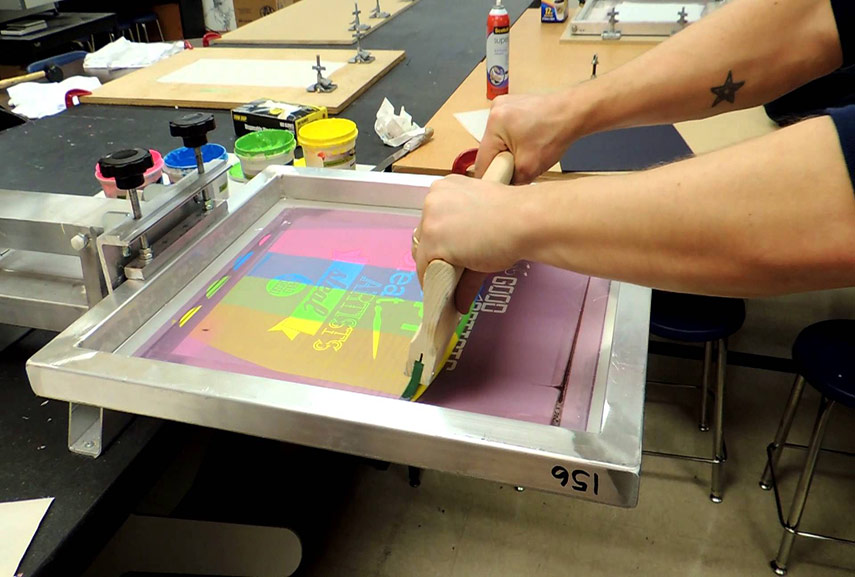

Comprehending the screen printing process involves numerous essential steps that transform a layout into a substantial product. A picture is created and then moved onto a screen, which is normally made of a fine mesh material. A stencil is used, allowing only certain locations of the screen to pass ink. Next, the screen is positioned over the substratum, whether it be fabric, paper, or one more product.

A squeegee is after that utilized to push ink through the open locations of the stencil onto the substratum. This procedure can be duplicated for numerous colors, needing exact alignment for every layer. After printing, the thing typically undergoes a healing process to set the ink, guaranteeing resilience and vibrancy. This methodical method makes screen printing a functional and reliable technique for generating high-quality designs on a selection of products, providing to both artistic and industrial needs.

Tips for Getting Going With Screen Printing

Beginning on a screen printing trip can be both amazing and challenging for novices. To assure a smooth intro, it is essential to begin with the appropriate devices. Spending in a basic screen printing package can provide necessary devices without overwhelming prices. Beginners must likewise familiarize themselves with the screen printing process, including preparing screens, blending inks, and appropriate printing techniques.

Connecting with various other screen printers, either online or in neighborhood workshops, can offer assistance and ideas. Keeping a tidy work area and arranging materials can simplify the printing process, making it extra reliable and enjoyable. read more 10:9 Design contact. With persistence and method, novices can discover success worldwide of screen printing

Often Asked Concerns

What Materials Can Be Made Use Of for Screen Printing?

Screen printing can use different materials, including cotton, plastic, polyester, and paper. Furthermore, inks such as water-based, plastisol, and discharge are frequently used, permitting varied applications throughout fabrics, product packaging, and advertising products.

How Long Does Screen Printing Last on Clothes?

Screen printing can last a number of years on garments, depending on factors like ink quality, textile kind, and treatment guidelines. Appropriate washing and handling substantially boost the resilience, ensuring the style continues to be vivid over time.

Can Screen Printing Be Done at Home?

Yes, screen printing can be done in the house. With the best devices and materials, people can produce custom styles on numerous garments, enabling for personal expression and imagination in their jobs without needing expert solutions.

What Is the Price of Setting up a Screen Printing Organization?

Establishing a display printing business typically costs between $2,000 and $10,000, depending on devices quality, materials, and work space. Additional costs include advertising, utilities, and recurring supplies, which can significantly affect general financial investment.

Just how Do I Clean Screen Printing Screens?

To clean screen printing screens, one ought to use a solvent to eliminate ink, complied with by a stress washing machine or hose pipe to get rid of deposit. A mild scrub with a brush ensures that screens stay in ideal condition.

In the 20th century, screen printing acquired popularity in the United States, specifically with the increase of industrial printing and advertising. Additionally, screen printing finds use in electronic devices, where it is utilized to use conductive inks on circuit boards. Recognizing the screen printing process involves numerous vital steps that change a layout into a substantial product - 10:9 Design Abilene. Screen printing can last numerous years on garments, depending on factors like ink high quality, material kind, and treatment instructions. To clean up screen printing displays, one must use a solvent to get rid of ink, followed by a stress washing machine or hose to eliminate residue